Manufacturing Strength Index Calculator

Calculate Your State's Manufacturing Strength

Compare your state against the national leader using the three key metrics from the Manufacturing Strength Index methodology.

Your Manufacturing Strength Index

How it's calculated: Normalized values (0-100) for output, jobs, and wages are summed for a composite score.

Key Metrics Reference

These are the benchmark values for Texas, the 2025 manufacturing leader according to the Manufacturing Strength Index methodology.

When you hear the phrase “manufacturing powerhouse,” you probably picture a state with massive factories, high‑tech jobs, and a robust export market. In 2025 the data point to one clear front‑runner, but the story behind the numbers involves infrastructure, policy, and industry mix. This guide breaks down who’s on top, why they got there, and what the ranking means for businesses and job‑seekers.

Quick Snapshot: The Current Leader

Texas is the state that leads U.S. manufacturing in 2025 when you look at total output value, employment, and average wages. According to the latest Bureau of Economic Analysis (BEA) figures, Texas generated $421billion in manufacturing value‑added, employed 1.14million workers, and paid an average annual salary of $78,900.

How We Measure “Leadership”

To keep the comparison fair we weight three core metrics:

- Output value - total dollar value of goods produced.

- Employment - number of full‑time manufacturing jobs.

- Average wage - compensation per worker, adjusted for inflation.

Each metric is normalized to a 0‑100 scale, then summed for a composite score. The methodology follows the Economic Policy Institute’s “Manufacturing Strength Index,” which is widely cited in policy circles.

Top Five Manufacturing States in 2025

| State | Output Value (Billions USD) | Manufacturing Jobs (Thousands) | Avg. Wage (USD) | Composite Score |

|---|---|---|---|---|

| Texas | 421 | 1,140 | 78,900 | 92.4 |

| California | 398 | 983 | 84,300 | 89.7 |

| Ohio | 287 | 842 | 71,500 | 85.1 |

| Illinois | 264 | 801 | 73,200 | 84.3 |

| Indiana | 221 | 732 | 69,800 | 81.9 |

Why Texas Takes the Crown

Three big factors set Texas apart:

- Energy advantage - The Lone Star State’s access to cheap natural gas and a growing renewable portfolio lowers production costs for chemicals, plastics, and metal processing.

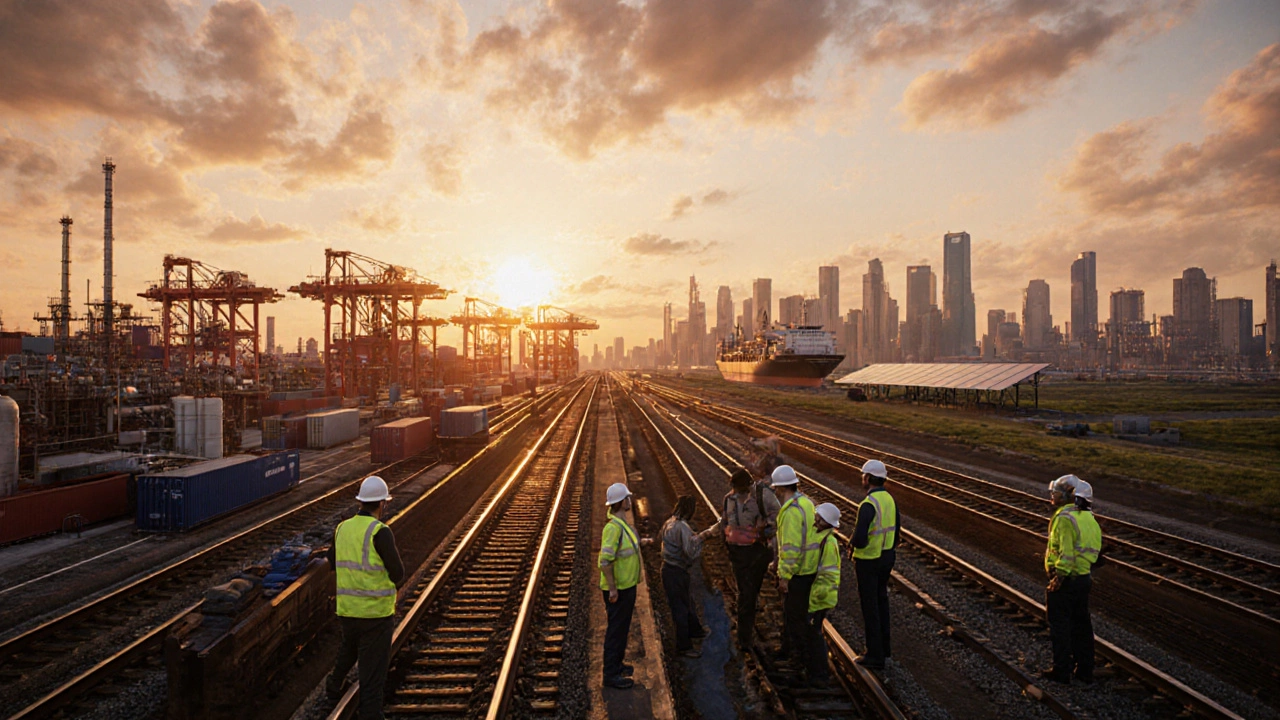

- Logistics hub - With the Port of Houston, an extensive rail network, and 400+ miles of coastline, Texas moves more goods per mile than any other state.

- Business‑friendly climate - No state income tax, streamlined permitting, and generous tax abatements attract both legacy manufacturers and high‑tech startups.

These strengths are reinforced by a skilled workforce; the Texas Workforce Commission reports a 4.8% increase in manufacturing apprenticeships between 2022 and 2025.

How the Other Leaders Differ

California leads in high‑tech electronics and aerospace but lags behind on wage‑adjusted productivity because of higher regulatory costs. Ohio shines in automotive and steel, leveraging the “Rust Belt” legacy and recent federal infrastructure grants. Illinois benefits from its central location and a strong food‑processing sector, while Indiana has specialized in precision equipment and medical device manufacturing.

Trends to Watch Through 2028

The manufacturing landscape is shifting fast. Three trends could reshuffle the rankings:

- Automation adoption - States that invest in robotics tax credits (like Michigan’s 2023 program) see faster productivity gains.

- Supply‑chain reshoring - Companies moving production back to U.S. soil favor states with strong logistics, potentially boosting the Mid‑Atlantic corridor.

- Green manufacturing incentives - Federal tax credits for low‑carbon processes are already spurring projects in North Carolina and Tennessee.

Monitoring these signals helps businesses decide where to locate new plants or expand existing ones.

What This Means for Decision‑Makers

If you’re a CFO evaluating plant locations, start with the composite score but then drill down to industry‑specific data. For example, a solar‑panel manufacturer will value Arizona’s solar‑friendly policies more than Texas’s energy cost advantage.

HR leaders should consider workforce pipelines. Texas’ apprenticeship growth outpaces the national average by 1.2percentage points, while Ohio’s community‑college programs offer more customized manufacturing curricula.

Finally, policy analysts can use the Manufacturing Strength Index to argue for targeted incentives in lagging states-especially those with high unemployment but untapped industrial space, such as Mississippi.

Quick Checklist for Manufacturing Site Selection

- Confirm the state’s composite score aligns with your primary metric (output, jobs, or wages).

- Assess logistics: proximity to ports, rail, and major highways.

- Review incentive programs: tax abatements, workforce training grants, green‑tech credits.

- Check labor market data: average wage, skill‑set availability, apprenticeship growth.

- Map future trends: automation support, reshoring pipelines, sustainability targets.

Frequently Asked Questions

Which state has the highest manufacturing wages?

California leads with an average manufacturing wage of $84,300, driven by its high‑tech sectors and strong union presence.

How does Texas compare to the national average in manufacturing output?

Texas accounts for roughly 13% of the nation’s total manufacturing value‑added, while the U.S. average per state sits near 5%.

Are there any states closing the gap with Texas?

North Carolina and Georgia have seen double‑digit growth in output and employment since 2022, thanks to strong logistics incentives, but they remain a few points behind in the composite score.

What role do tax incentives play in manufacturing location decisions?

Tax incentives can reduce capital expenditures by 5‑15%. States like Texas and Indiana offer credits for equipment purchases, while Michigan provides grants for automation projects. Companies typically perform a net‑present‑value analysis to weigh incentives against other cost factors.

Where can I find the most recent manufacturing statistics?

The U.S. Bureau of Economic Analysis (BEA) releases quarterly state‑level manufacturing value‑added tables, and the Bureau of Labor Statistics (BLS) publishes monthly employment numbers. Both agencies offer downloadable CSV files for deeper analysis.