Local Manufacturing Cost Calculator

Calculate Your Savings

When you hear "local manufacturing," you might picture a small factory down the road making things right where you live. But it’s more than that. In 2026, local manufacturing means building products within your own country or region-using local labor, materials, and infrastructure-instead of shipping parts halfway across the world. Governments are pushing this hard, not just to create jobs, but to fix broken supply chains, cut carbon emissions, and keep money circulating in local economies.

Why Local Manufacturing Matters Now

After the pandemic, countries saw how fragile global supply chains really are. A factory in China shuts down? Your phone charger disappears from shelves. A shipping container gets stuck in the Suez Canal? Your car parts don’t arrive. That’s why places like the UK, the US, and the EU are rewriting their industrial policies. The UK’s local manufacturing push isn’t just about patriotism-it’s about survival.

In 2024, the UK government launched the Made in Britain initiative, offering grants to small factories that switch from importing components to making them locally. In Birmingham, where I live, a family-run metalworking shop that used to buy screws from Poland now sources them from a supplier in Wolverhampton. They got a £45,000 grant to upgrade their CNC machines. That’s the kind of shift happening everywhere.

What Counts as "Local"?

"Local" doesn’t mean your town. It usually means your country-or a defined economic region. In the EU, "local" might mean within the single market. In the UK, it’s anything made within Great Britain or Northern Ireland. But there’s a catch: local doesn’t always mean 100% British-made. A car assembled in Coventry might have German engines and Korean screens. That’s still considered local manufacturing if the final assembly, quality control, and most of the jobs happen here.

The government doesn’t demand every screw is British. It looks at value added. If 60% or more of the product’s cost comes from UK-based labor, materials, and processing, it qualifies for support. That’s the rule under the Industrial Strategy Challenge Fund.

How Government Schemes Support Local Manufacturing

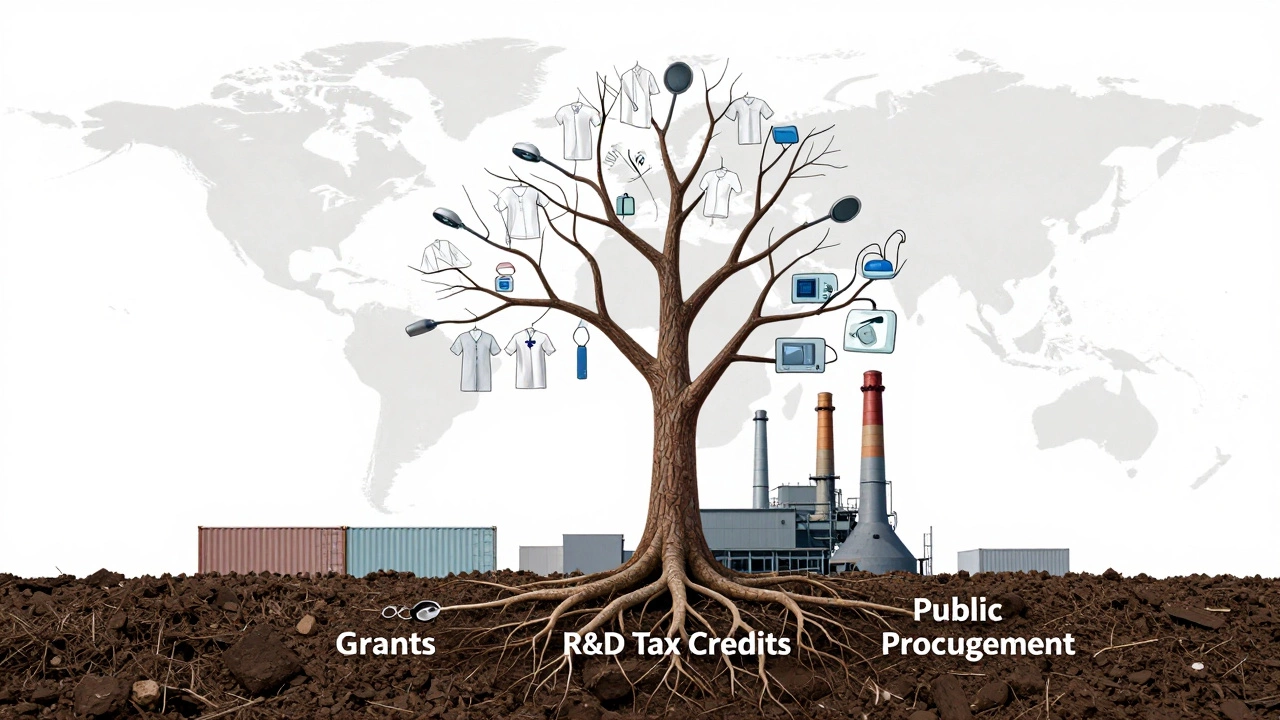

There are three main ways the government helps local makers:

- Grants for equipment upgrades - If you’re a small factory replacing old tools with automated ones, you can get up to 30% of the cost covered. The Manufacturing Growth Programme has helped over 2,300 businesses since 2022.

- Tax breaks for R&D - Companies developing new local production methods get up to 25% of their R&D costs back as a tax credit. That’s how a Sheffield-based toolmaker developed a new way to recycle scrap steel into high-grade parts.

- Public procurement rules - Government departments now have to give preference to locally made goods in contracts under £5 million. That means hospitals, schools, and councils are buying British-made hospital gowns, school desks, and streetlights-even if they cost 10% more.

These aren’t just handouts. They’re incentives tied to results. If you take a grant, you have to hire locally, hit production targets, and report your output. No free rides.

Local vs. Global: The Real Trade-Offs

Some people say local manufacturing is too expensive. And they’re right-sometimes. Making a smartphone entirely in the UK would cost three times more than making it in Vietnam. But that’s not the full picture.

Here’s what global manufacturing hides:

- Shipping costs that spike during wars or fuel crises

- Quality control delays when you can’t visit the factory

- Hidden environmental costs-every item shipped from Asia adds 1.5kg of CO₂ on average

- Lost skills-when factories close, engineers leave the industry for good

Local manufacturing isn’t about being the cheapest. It’s about being more reliable, more responsive, and more sustainable. A UK-based medical device maker can redesign a ventilator part in a week. A factory in Bangladesh needs 14 weeks just to get the specs approved.

Who Benefits Most?

It’s not just big corporations. Small and medium-sized manufacturers are the real winners. In 2025, 78% of the £1.2 billion in government manufacturing support went to businesses with fewer than 250 employees. That’s a big shift from 10 years ago, when most aid went to giants like Rolls-Royce or Jaguar Land Rover.

Take a bakery in Leicester that started making its own oven trays locally instead of importing them from Turkey. They now supply 12 other bakeries. They hired two welders. They reduced their lead time from 6 weeks to 3. And they cut their carbon footprint by 40%.

That’s the ripple effect. One small shop making something locally creates jobs, reduces waste, and builds community resilience.

Challenges and Pitfalls

It’s not all smooth sailing. Many small makers struggle with:

- Access to skilled workers-there are 80,000 unfilled engineering jobs in the UK

- High energy costs-electricity for factories is 35% more expensive than in Germany

- Lack of access to capital-banks still see manufacturing as risky

And not every product should be made locally. You won’t see UK-made smartphones or cheap plastic toys. The goal isn’t to make everything here. It’s to make what matters: critical components, medical gear, food packaging, defense tech, and infrastructure parts.

Government schemes focus on these areas because they’re too important to risk on overseas suppliers.

What’s Next for Local Manufacturing?

By 2027, the UK aims to raise the share of domestic manufacturing in its GDP from 9% to 12%. That’s not massive, but it’s a real step. New digital tools are helping too. AI-driven demand forecasting lets small factories know exactly how many parts to make-no overstock, no waste.

Local supply networks are forming. In the West Midlands, 140 small factories now share a logistics hub that cuts delivery times by half. It’s called the Midlands Manufacturing Network. It’s not fancy. But it works.

What’s clear is this: local manufacturing isn’t a trend. It’s a long-term strategy. And for the first time in decades, the government is backing it with real money, real rules, and real accountability.

Is local manufacturing the same as "Made in Britain"?

"Made in Britain" is a certification label, not a legal term. Local manufacturing refers to any production that happens within the UK, regardless of branding. But if a product carries the "Made in Britain" label, it must meet strict criteria: final assembly, significant processing, and at least 50% of its value added must occur in the UK. The label is verified by a nonprofit, so it’s trustworthy.

Can small businesses really compete with big factories?

Yes-if they focus on niche products, speed, and customization. Big factories thrive on volume. Small ones thrive on agility. A local maker can produce 50 custom medical trays in a week. A big factory would need months to retool for that. Government grants help small businesses buy the tools they need, and public procurement rules give them a foot in the door.

Does local manufacturing mean higher prices for consumers?

Sometimes, yes-but not always. For things like streetlights, school furniture, or hospital equipment, the price difference is often less than 10%. And when you factor in faster delivery, fewer returns, and lower environmental costs, the real value goes up. Plus, many local products last longer. A UK-made metal bench won’t crack in winter like a cheap imported plastic one.

Are government schemes only for factories?

No. The schemes also cover design studios, prototyping labs, and even software companies that build digital tools for manufacturers. If your work directly supports physical production in the UK-like creating 3D printing files for a local workshop-you can qualify. The focus is on the outcome, not the job title.

What happens if a company takes a grant but doesn’t deliver?

They have to pay it back-with interest. The government tracks output, jobs created, and carbon savings. If you don’t hit your targets, you get a warning. Miss a second deadline? The grant is clawed back. There’s no tolerance for fraud. The system is designed to reward real results, not paperwork.