Manufacturer Criteria: What Makes a Good Manufacturer in India

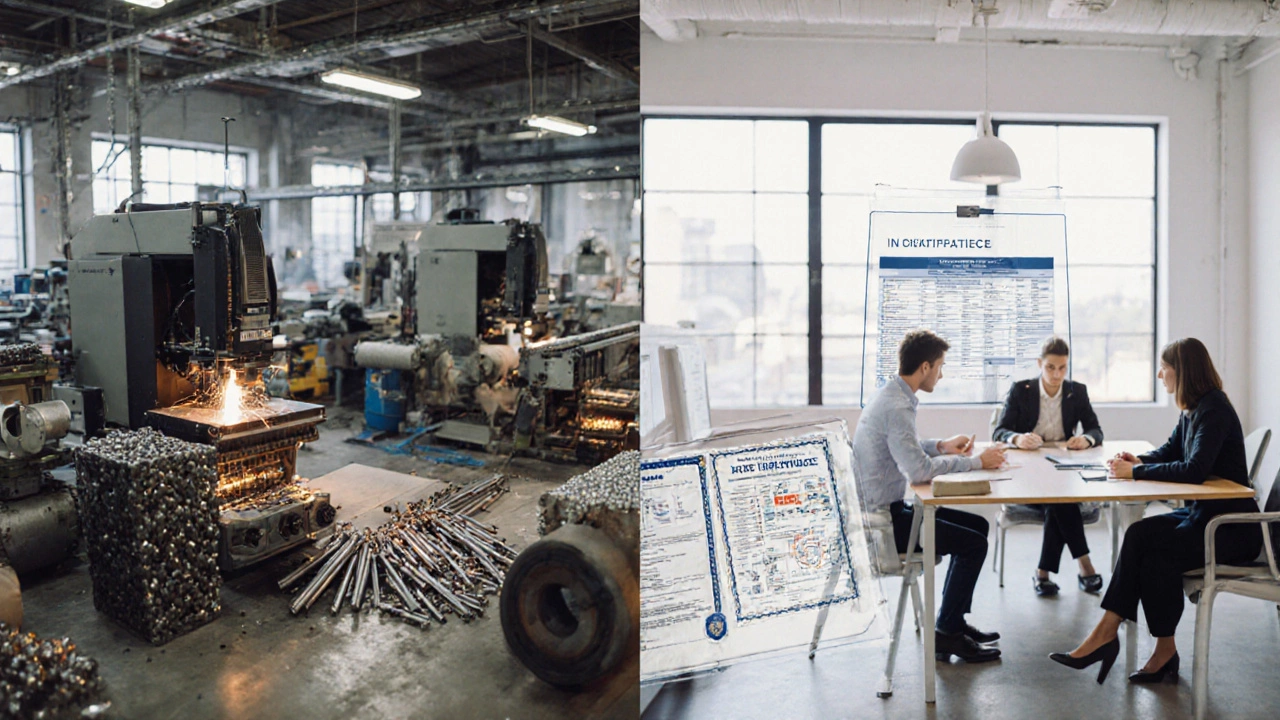

When you hear manufacturer criteria, the set of standards and practices that define reliable production in India. Also known as production standards, it's not just about having a factory—it's about how consistently you deliver quality, meet deadlines, and adapt to real-world needs. Too many people think a manufacturer is just someone with machines. But the best ones? They understand supply chains, labor skills, and even local power fluctuations. In India, where small factories make up over 90% of manufacturing units, the real winners aren’t the biggest—they’re the ones who get the details right.

Take quality control, the systematic process of ensuring products meet defined standards before they leave the factory. It’s not a one-time check—it’s built into every step, from raw material sorting to final packaging. Look at Gujarat’s chemical plants or Tamil Nadu’s electronics hubs: they don’t win contracts because they’re cheap. They win because their defect rates are lower than global averages. Then there’s small manufacturer, a business with fewer than 50 employees that produces goods locally, often with custom processes. These are the hidden engines of India’s manufacturing rise. They don’t need huge budgets. They need clear criteria: consistent output, honest communication, and the ability to scale without losing control.

What about Indian manufacturer, a production entity based in India that serves domestic or global markets with locally sourced inputs and labor? The best ones don’t copy China. They don’t chase subsidies blindly. They build trust—by showing up on time, fixing problems fast, and letting customers see their floors. You’ll find this in the textile units of Surat, the metal fabrication shops in Ludhiana, and the food processing units in Punjab. These aren’t faceless factories. They’re teams that know their machines, their workers, and their customers by name.

And here’s the thing: manufacturer criteria aren’t just for buyers. If you’re starting a small production business, these same rules are your checklist. Can you test your product? Can you handle 100 units today and 1,000 next month? Do your workers know why quality matters? If yes, you’re already ahead of most. The posts below show real examples—how someone turned scrap metal into export-ready parts, how a home-based maker cracked the food packaging game, and why Gujarat’s chemical factories are outpacing global rivals. No fluff. Just what works.

What Qualifies as a Manufacturer? Clear Criteria and Real‑World Examples

Learn the exact legal criteria that define a manufacturer, from facility control to licensing, tax benefits, and real-world examples.

ManufacturingLatest Posts

Tags

- manufacturing

- small scale manufacturing

- plastic manufacturing

- India

- plastic pollution

- food processing

- textile industry

- government schemes

- electronics manufacturing

- small business

- steel manufacturing

- startup ideas

- production

- textile manufacturers India

- manufacturing business ideas

- business ideas

- chemical manufacturers India

- electronics manufacturing India

- steel manufacturing plants

- manufacturing business