Manufacturing Method Selector

Find the best manufacturing method for your product based on your production volume, customization requirements, and budget constraints.

Recommended Manufacturing Method

Method Comparison

Mass Production

Ideal for high-volume, identical products

Best for 10,000+ units per year

Lowest cost per unit

Batch Production

Ideal for moderate volumes with variety

Best for 100-5,000 units per batch

Balance of cost and flexibility

Job Shop Production

Ideal for custom, one-off items

Best for 1-100 custom units

High cost per unit

When you think about how things are made - from your phone to your car seat to the medicine in your cabinet - it’s easy to assume everything is made the same way. But the truth is, manufacturers choose one of three core methods based on what they’re building, how many units they need, and how much flexibility they need. These aren’t just textbook terms. They’re real decisions that shape costs, timelines, and even the quality of what ends up in your hands.

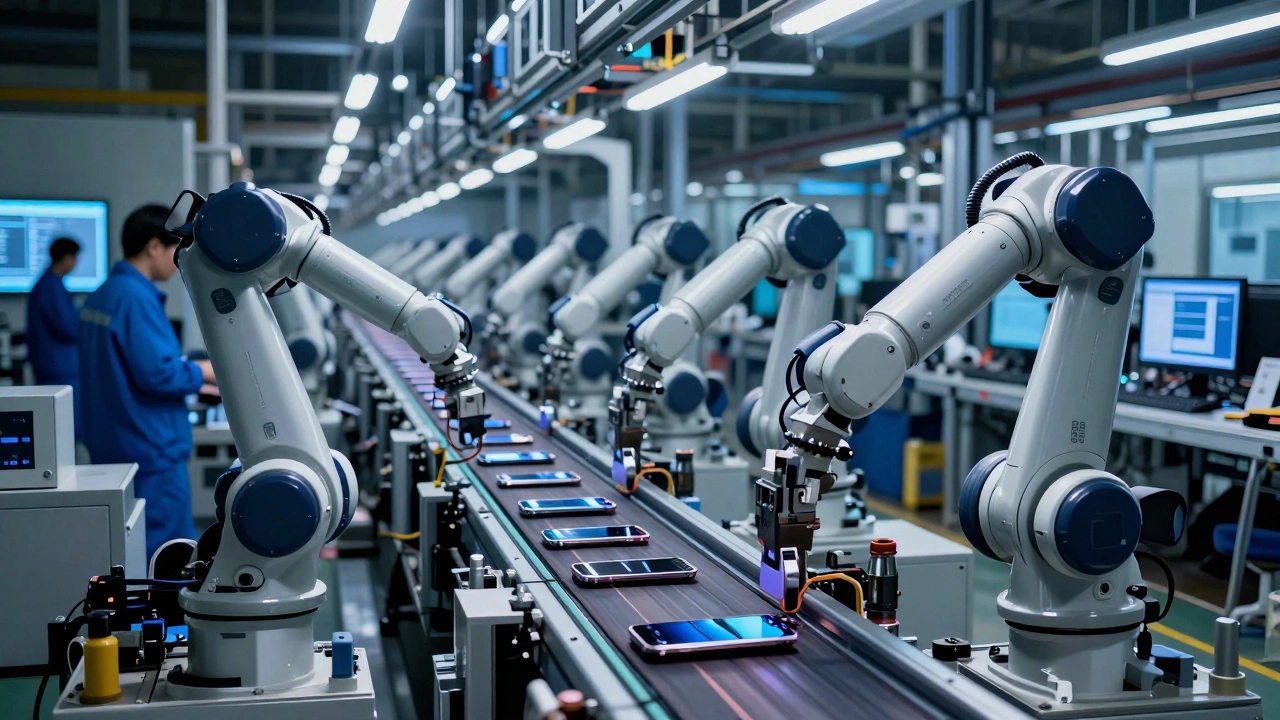

Mass Production: Making Thousands the Same Way

Mass production is what most people picture when they think of factories: endless lines of identical products moving past workers or robots. Think Coca-Cola bottles, smartphone chargers, or car engines. This method works best when you need a huge volume of the exact same item, over and over.

The setup is expensive. You need specialized machinery, automated assembly lines, and precise tooling. But once it’s running, the cost per unit drops hard. A single car plant can produce 1,000 vehicles a day because every step is optimized for speed and repetition. Companies like Toyota and Apple rely on this method because they sell millions of units yearly.

Here’s the catch: mass production is inflexible. Change the design? You’re shutting down the line for weeks. Fix a defect? It might mean recalling thousands of units. That’s why it’s only used when demand is predictable and stable. If you’re making something new or niche, this isn’t your play.

Batch Production: Making in Groups, Not One by One

Batch production sits between mass production and custom work. Instead of making 10,000 of the same thing all at once, you make 500, then switch to a different product, then another 500 of the first. It’s common in food packaging, pharmaceuticals, and even custom electronics.

Imagine a bakery that makes 200 chocolate chip cookies, then switches to 150 oatmeal raisin, then 100 blueberry muffins. Each batch runs through the same oven and mixing equipment, but the ingredients and settings change. That’s batch production.

This method gives you flexibility without the high cost of custom work. You can test new products, respond to seasonal demand, or manage inventory better. A small pharma company might produce 1,000 bottles of a cold remedy in January, then switch to allergy pills in April. The equipment stays the same; only the formula and packaging change.

Downsides? There’s downtime between batches. Cleaning machines, reconfiguring settings, and training staff for each new run adds time and cost. But for most mid-sized manufacturers, this is the sweet spot - enough volume to be efficient, enough variety to stay agile.

Job Shop Production: Custom Work, One at a Time

If you need something unique - a one-off machine part, a custom wedding dress, or a prototype for a new drone - you’re looking at job shop production. This is the opposite of mass production. Instead of repeating the same process, every job is different.

Think of a machine shop in Birmingham that builds custom gearboxes for vintage tractors. Each order has different dimensions, materials, and tolerances. Workers use CNC machines, lathes, and manual tools to build each unit from scratch. No two jobs are identical.

Job shops thrive on skill, not speed. They rely on experienced machinists, engineers, and project managers who can read blueprints, troubleshoot on the fly, and adapt quickly. The cost per unit is high because there’s no economies of scale. But the value? It’s in the customization. You can’t buy this on Amazon.

This method is common in aerospace, medical device repair, and industrial equipment repair. A hospital might need a one-off bracket to hold a rare piece of imaging equipment. Only a job shop can handle that. The trade-off? Lead times are longer, and prices are higher. But if you need something that doesn’t exist yet, this is your only option.

How Do You Choose the Right Method?

It’s not about which method is ‘better.’ It’s about matching your needs.

- Use mass production if you’re making 10,000+ of the same thing and demand won’t change for years.

- Use batch production if you make 100-5,000 units at a time, need variety, and want to avoid constant redesigns.

- Use job shop production if every product is unique, orders are small, and customization matters more than speed.

Many companies use a mix. A furniture maker might mass-produce standard chairs, batch-produce seasonal collections, and take job shop orders for custom dining tables. The key is knowing which method fits each product line.

What’s Changing in Manufacturing Today?

Technology is blurring the lines between these methods. 3D printing lets job shops produce small batches without tooling. AI-driven scheduling helps batch producers switch faster. Even mass production lines now use modular systems that allow quick product changes.

But the core principles haven’t changed. You still need to answer the same questions: How many? How often? How different? The tools evolve, but the strategy stays the same.

Why This Matters for Small Businesses and Startups

If you’re launching a product, choosing the wrong method can sink you. Startups often try to mass-produce too early. They spend $200,000 on tooling for 1,000 units - then only sell 300. That’s a disaster.

Start with job shop or batch production. Test the market. Get feedback. Prove demand. Then scale. Many successful brands - like Dyson or Allbirds - began with small batches before moving to mass production. They didn’t gamble on volume. They built it step by step.

Government grants and innovation funds in the UK often support small manufacturers using batch or job shop methods. They know innovation doesn’t come from giant factories alone. It comes from flexibility, experimentation, and smart scaling.

Real-World Examples You’ve Used Today

- Your coffee mug? Mass-produced in China, thousands per hour.

- Your prescription pills? Batch-produced - 5,000 bottles of your dose, then 3,000 of your neighbor’s.

- Your custom orthopedic insole? Made one at a time in a job shop using a 3D scan of your foot.

You interact with all three methods every day. The difference is in the scale, the cost, and the control. Understanding them helps you make smarter choices - whether you’re buying, building, or investing.

What’s the cheapest manufacturing method for small quantities?

Job shop production is usually the only option for small quantities, but it’s not cheap. For under 100 units, 3D printing or CNC machining is often the most cost-effective. Batch production only makes sense when you’re producing at least 50-100 units of the same item. If you need 10 custom parts, pay for the job shop. If you need 500 identical ones, go batch.

Can a company switch between manufacturing methods?

Yes, and many do. A company might start with job shop production to test a product, then move to batch production as demand grows. Once sales hit a certain volume - say, 50,000 units a year - they’ll invest in mass production. The key is planning for scalability from day one. Don’t build a job shop with mass production equipment - it’ll be too slow. Don’t buy a $2 million assembly line for 1,000 units - it’ll break your budget.

Which manufacturing method is most affected by supply chain issues?

Mass production is the most vulnerable. It depends on constant, uninterrupted flows of parts, materials, and labor. A single delayed component can stop an entire line. Batch production has more buffer - you can pause one batch and start another. Job shops are the most resilient. If one material is late, they just switch to another job. That’s why small manufacturers often survive supply chain shocks better than big factories.

Do government schemes support all three methods?

Yes, but differently. UK government grants like the Made Smarter programme focus on helping small manufacturers adopt automation - often in batch or job shop settings. Mass production gets support through tax breaks for capital investment. Job shops benefit from innovation grants for prototyping and R&D. If you’re a small business, look for schemes that match your scale, not your ambition.

Is one method more sustainable than the others?

Not inherently. Mass production can be efficient per unit but creates waste if demand drops. Job shops use less material overall because they make only what’s ordered. Batch production can be optimized for sustainability by grouping similar materials or using reusable packaging. The real sustainability win comes from choosing the right method for your product - avoiding overproduction is the biggest factor.

Final Thought: It’s Not About the Method - It’s About the Match

There’s no ‘best’ manufacturing method. Only the right one for your product, your market, and your stage of growth. The companies that win aren’t the ones with the biggest factories. They’re the ones who know when to scale, when to stay small, and when to change direction.