Manufacturing Cost Calculator

Calculate Your Minimum Retail Price

Determine if your product idea is financially viable based on real costs and industry-standard pricing

Your Results

According to the article: "Add those up. Multiply by 2.5 to 3. That's your minimum retail price."

You’ve got an idea. Maybe it’s a better kitchen gadget, a reusable packaging solution, or a custom tool for hobbyists. You’ve sketched it, tested it, even shown it to friends who said, ‘You should sell this.’ Now what? Starting manufacturing isn’t about big factories or million-dollar loans. It’s about turning your idea into something real-step by step, with limited cash and maximum hustle.

Start with a real problem, not just a cool design

Too many people jump straight to making a prototype because they like how something looks. That’s not manufacturing. That’s crafting. Real manufacturing starts with a problem people are willing to pay to fix. Ask yourself: Who exactly struggles with this? How often? What are they doing right now to solve it? If the answer is ‘nothing’ or ‘making do,’ you’ve got a gap. If they’re buying something cheap, flimsy, or overpriced from Amazon, you’ve got an opening. I knew a guy in Birmingham who made a simple phone stand for gardeners. He noticed people were holding phones in one hand while weeding, and their backs were killing them. He didn’t invent a new tech-he just made a lightweight, foldable stand that clipped to a fence. Sold 300 units in three months. His idea wasn’t revolutionary. It was useful.Build a working prototype, not a pretty model

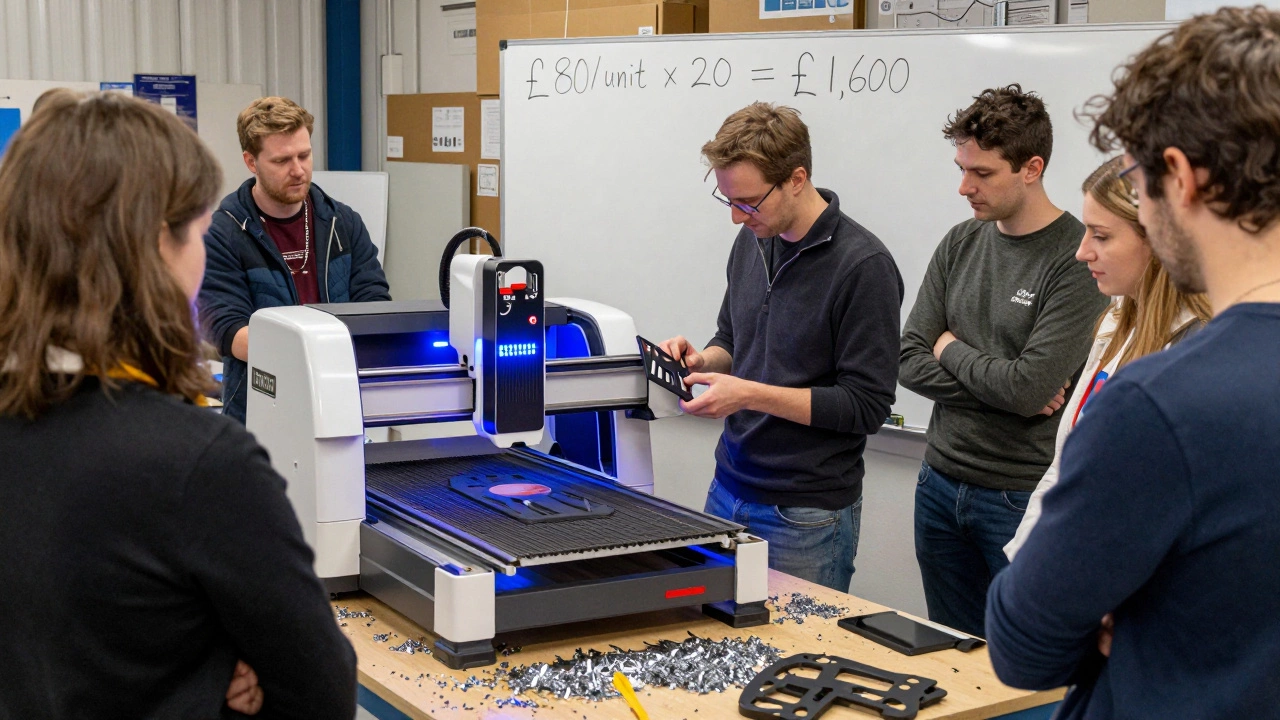

You don’t need a 3D printer to start. You need something that works. Cardboard, duct tape, old parts from your garage, or even clay can be your first materials. Take the time to test it. Use it like your customer would. Break it. Fix it. Break it again. If your prototype can’t survive a week of real use, you’re not ready to make more than one. Local makerspaces in Birmingham-like Make:it or The Innovation Hub-offer cheap access to tools, laser cutters, and experienced people who’ve done this before. Spend £20 to borrow a CNC router for a day instead of spending £500 on a cheap one you’ll never use.Find your first 10 customers before you make anything

Manufacturing is expensive. The biggest mistake? Making 500 units before you know anyone wants them. Instead, find your first 10 buyers before you cut a single piece of plastic or metal. Use Instagram, Facebook groups, Reddit threads, or even local markets. Post your prototype. Ask: ‘Would you buy this for £15?’ If 8 out of 10 say yes, you’ve got validation. If only 3 say yes, go back to the drawing board. Don’t say ‘I’ll launch on Kickstarter.’ That’s not validation. That’s hoping. Real validation is someone handing you cash or a card and saying, ‘I’ll take one.’

Start small with local suppliers, not overseas factories

You don’t need to fly to Shenzhen. The UK has hundreds of small manufacturers who take tiny orders. Look for:- Local CNC machining shops (they often do runs of 10-50 pieces)

- Injection moulding specialists who offer low-volume tooling

- Print-on-demand services for packaging or labels

- Textile workshops if your product needs fabric or stitching

Don’t over-engineer the packaging

Your product doesn’t need a luxury box with foam inserts and embossed logos. That’s for big brands with marketing budgets. Use recycled cardboard. Print your logo with a basic inkjet printer. Use biodegradable tape. Include a simple instruction sheet printed on one side of an A5 sheet. Packaging should protect the product, not impress investors. Save the fancy design for when you’re selling thousands a month.Price it right from day one

Here’s the math you need:- Cost of materials per unit

- Labour cost (your time + any helper)

- Tooling or setup fees (divided by number of units)

- Shipping and packaging

- Platform fees (eBay, Etsy, Shopify)

Test your sales channel before you make more

Where will people buy this? Don’t assume your website will work. Test first. Try selling on:- Etsy (great for handmade, niche items)

- eBay (good for testing demand)

- Local craft fairs or farmers markets (face-to-face feedback is gold)

- Facebook Marketplace (free, local, fast)

Scale only when you’re reinvesting profits, not loans

Don’t take out a loan to scale. Don’t use credit cards. Reinvest your first £500 in more materials. Then £1,000. Then £2,000. Each time you increase production, negotiate better rates with your supplier. Ask for volume discounts. Bundle orders. Share tooling costs with another small maker. One maker in Coventry started by making 10 silicone baking mats a week. After 6 months, he was making 200. He didn’t hire staff-he just improved his process. He now sells to 12 independent kitchen shops across the Midlands.What you’re really building isn’t a product-it’s a system

Manufacturing isn’t about making one thing. It’s about making the same thing, again and again, with less waste, less time, and more consistency. Your goal isn’t to become a factory owner. It’s to create a repeatable process where you can hand off parts to others-like packaging, shipping, or even assembly-so you can focus on what you do best: improving the product. Start small. Test fast. Listen harder than you talk. And never make more than you can sell in 30 days. That’s the only rule that matters.Do I need a patent to start manufacturing?

No. Most small-scale products don’t need patents. Filing one costs £100-£2,000 and takes 1-3 years. By then, your product might be outdated. Focus on being first to market, not first to file. If someone copies you, you’ll have better customer relationships, faster updates, and lower prices-things patents can’t protect.

Can I manufacture at home?

Yes-for simple products. Things like hand-sewn bags, printed stickers, wooden phone stands, or custom candles can be made in a garage or spare room. But if you’re using power tools, chemicals, or high heat, check your local council rules. Some areas restrict home manufacturing for safety or zoning reasons. Always prioritize safety over convenience.

How much money do I need to start?

You can start with under £500. That covers materials for 10-20 units, basic packaging, and a few ads on Facebook or Etsy. Many makers start with £100-£300. The key isn’t how much you spend-it’s how fast you learn from real sales. If you spend £1,000 and sell 3 units, you wasted money. If you spend £200 and sell 20, you’re on track.

What if my product fails?

It’s not failure-it’s data. Most first products don’t take off. That’s normal. Ask your customers why they didn’t buy. Was it too expensive? Too complicated? Not needed? Use that feedback to pivot. Many successful makers had 3-5 failed ideas before one stuck. The only real failure is not listening.

How long does it take to go from idea to sale?

As little as 2 weeks. If you’re using off-the-shelf parts and simple assembly, you can have a prototype ready in days and sell your first unit within two weeks. Most people take 3-6 months because they overthink it. Speed beats perfection in small-scale manufacturing. Get it out. Learn. Improve. Repeat.