Small Manufacturer Size Calculator

UK Small Manufacturer Eligibility Checker

This tool helps determine if your business qualifies as a small manufacturer according to UK standards and identifies potential support programs and growth strategies.

Eligibility Results

Eligible Support Programs

Recommended Growth Strategies

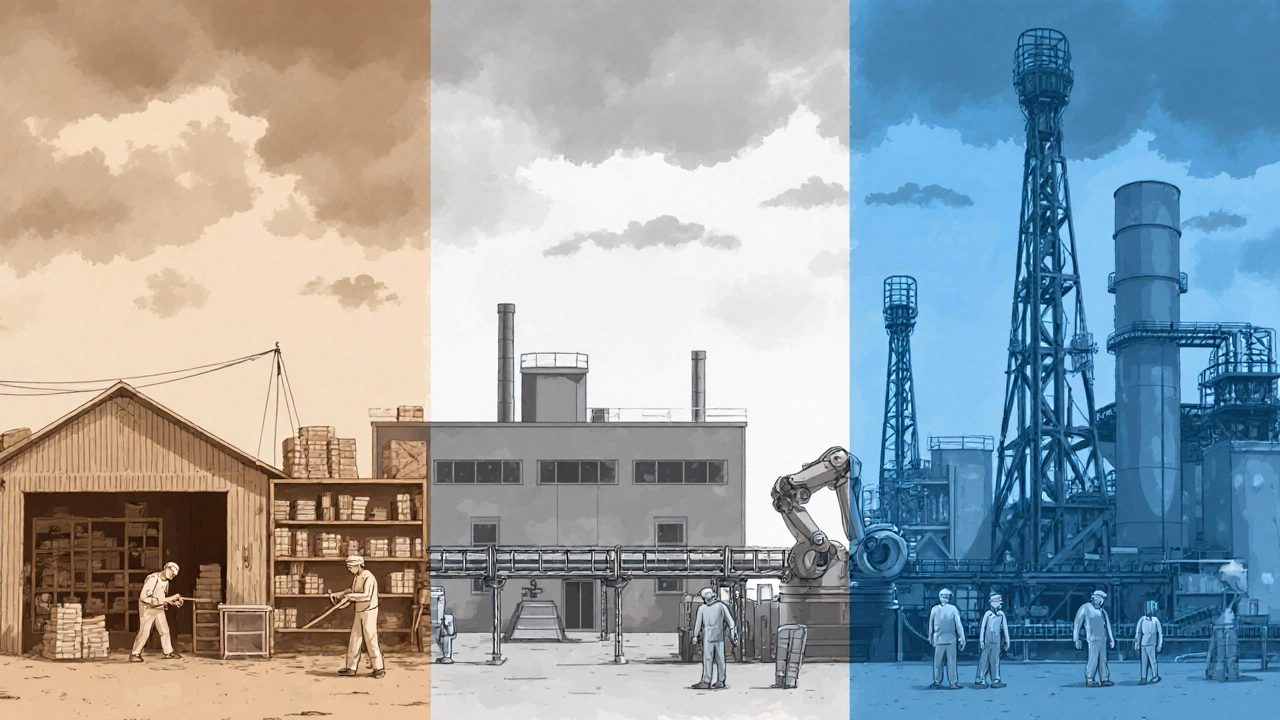

When you hear the term small manufacturer, you might picture a workshop tucked behind a row of houses or a modest factory on the outskirts of a town. The reality is a bit more nuanced, especially in today’s UK economy where the line between boutique production and industrial operation constantly shifts. This guide breaks down exactly what a small manufacturer is, how it differs from larger rivals, the sectors where they thrive, and the steps you can take to launch or scale one.

Defining a Small Manufacturer

Small manufacturer is a business that produces goods on a limited scale, typically employing fewer than 50 staff and generating annual turnover below £10 million in the UK. The definition varies by industry and region, but the core idea revolves around production capacity, workforce size, and market reach.

In the UK, the government often classifies these firms under the broader SME (Small and Medium-sized Enterprise) umbrella, using the European Commission thresholds: fewer than 250 employees and turnover under €50 million. While all small manufacturers are SMEs, not all SMEs are manufacturers - many are service‑oriented or retail.

Key Characteristics of Small Manufacturers

- Limited Production Capacity: Output ranges from a few hundred units a year to a few thousand, depending on the product and automation level.

- Flexible Operations: Small teams can pivot quickly, redesign products, or adopt custom orders without the bureaucracy of large plants.

- Local or Niche Markets: Many serve regional customers or specialize in high‑value, low‑volume items such as bespoke furniture or specialty foods.

- Capital Constraints: Access to financing is often tighter, making cash‑flow management a daily focus.

- Hands‑On Management: Owners usually wear multiple hats - from product design to sales and compliance.

How Small Manufacturers Differ from Medium and Large Counterparts

| Aspect | Small Manufacturer | Medium Manufacturer | Large Manufacturer |

|---|---|---|---|

| Employees | 1‑49 | 50‑249 | 250+ |

| Annual Turnover | Under £10 M | £10 M‑£100 M | Over £100 M |

| Production Volume | Low‑to‑moderate | Moderate‑to‑high | High‑to‑very high |

| Automation Level | Low‑to‑medium | Medium‑to‑high | High‑to‑very high |

| Decision Speed | Hours‑to‑days | Days‑to‑weeks | Weeks‑to‑months |

These differences affect everything from supply‑chain strategy to compliance requirements. Small manufacturers often rely on Lean Manufacturing principles that minimize waste and maximize flexibility, whereas larger firms can invest in extensive automation and global logistics networks.

Common Sectors Where Small Manufacturers Thrive

While you can find small manufacturers in almost any industry, a few sectors consistently host a higher concentration of boutique producers:

- Food & Drink - Artisan cheese, craft breweries, specialty confectionery.

- Textiles & Apparel - Sustainable fashion labels, custom tailoring, heritage weaving.

- Furniture & Woodcraft - Hand‑made wooden tables, reclaimed‑material décor.

- Electronics - Small‑batch printed‑circuit boards, DIY kits, niche sensors.

- Pharmaceutical & Cosmetics - Small‑scale compounding, natural skincare lines.

These niches often benefit from Cottage Industry a production model rooted in home‑based or community workshops, where craftsmanship and local branding add premium value.

Regulatory & Financial Landscape in the UK

Operating a manufacturing business in the UK means navigating several layers of regulation - health and safety, environmental standards, and product‑specific certifications. Small manufacturers can leverage a range of government schemes designed to level the playing field:

- UK Government Support - Grants from Innovate UK, the Manufacturing Advisory Service (MAS), and regional growth funds help with equipment purchases and R&D.

- Industrial Strategy - The latest 2024‑2029 plan emphasizes “Made in Britain” and offers tax incentives for low‑carbon production.

- Export Assistance - The Department for International Trade (DIT) provides market research and trade‑mission funding for SMEs seeking overseas customers.

Understanding the concept of Economies of Scale cost advantages that arise from increased production volume is crucial. Small manufacturers rarely achieve the same per‑unit cost reductions as large plants, so they must focus on differentiation, higher margins, or niche pricing.

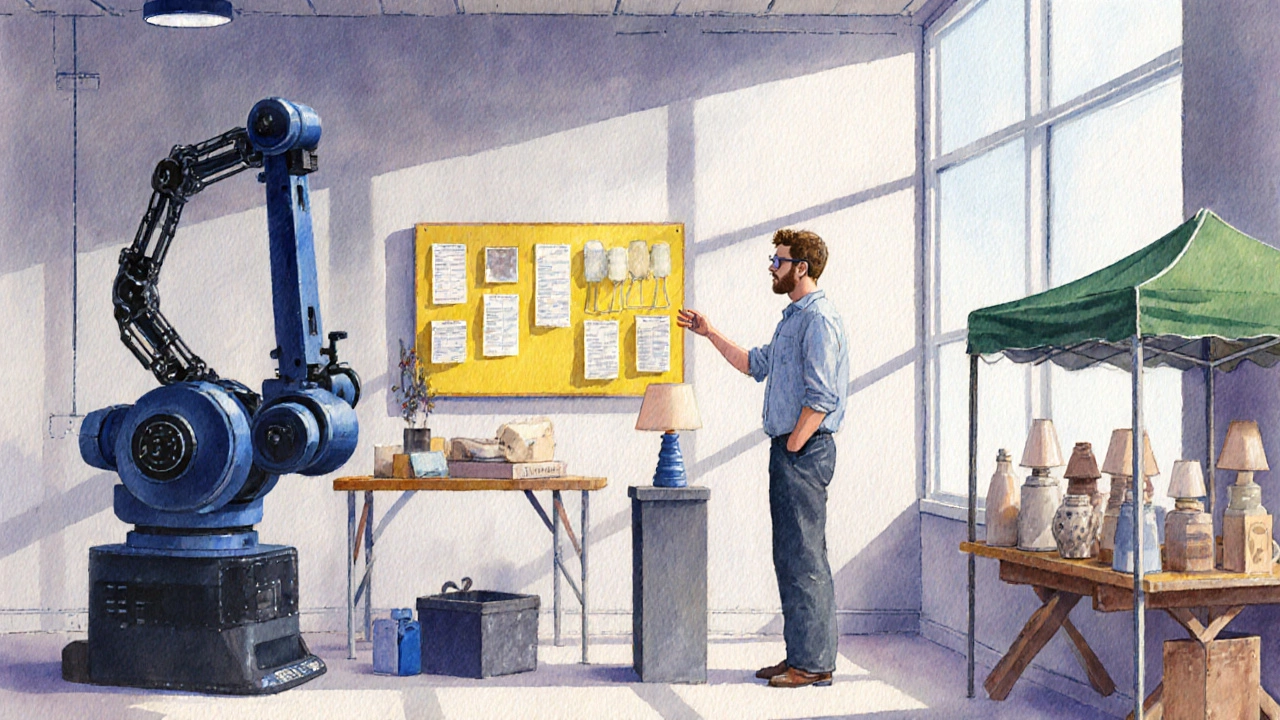

Growth Strategies for Small Manufacturers

Scaling a small manufacturing operation isn’t about turning into a giant overnight. Below are proven tactics that let you grow responsibly:

- Adopt Modular Automation: Instead of a full‑scale robotic line, invest in plug‑and‑play stations that can be added as demand rises.

- Leverage Contract Manufacturing: Partner with larger firms for components you don’t want to produce in‑house.

- Expand Market Reach: Use e‑commerce platforms, local farmer’s markets, or B2B marketplaces like Alibaba to find new buyers.

- Invest in Product Innovation: Small firms are nimble; develop unique features or sustainable materials that larger players can’t replicate quickly.

- Secure Flexible Funding: Consider peer‑to‑peer lending, government grants, or revenue‑based financing to avoid heavy debt.

Many successful small manufacturers also adopt Lean Manufacturing techniques-visual kanban boards, just‑in‑time inventory, and continuous improvement cycles-to keep waste low while meeting customer demand.

Challenges and How to Overcome Them

Running a small production unit comes with a unique set of headaches. Here’s a quick rundown of the most common issues and practical fixes:

- Cash‑Flow Gaps: Use invoice financing or negotiate shorter payment terms with customers.

- Talent Retention: Offer skill‑development programs and a clear path to ownership or profit‑sharing.

- Supply‑Chain Disruptions: Keep a buffer stock of critical raw materials and diversify suppliers.

- Regulatory Burdens: Subscribe to industry newsletters and join trade bodies like the British Manufacturing Federation for guidance.

- Technology Lag: Adopt cloud‑based ERP systems that scale with you; many have free starter tiers for SMEs.

Checklist for Starting a Small Manufacturing Business

Use this bite‑size checklist to keep your launch on track:

- Define the product niche and validate demand (surveys, pre‑orders).

- Draft a business plan that includes production capacity, cost sheet, and break‑even analysis.

- Secure premises that meet health‑safety and zoning requirements.

- Obtain necessary licenses (e.g., Food Standards Agency for food, CE marking for electronics).

- Set up accounting and choose an ERP/stock‑management tool.

- Apply for relevant UK Government Support grants.

- Choose suppliers and negotiate terms that allow for small‑batch orders.

- Implement Lean processes from day one.

- Launch a minimal viable product (MVP) and gather feedback.

- Iterate, scale production, and reinvest profits into automation.

Frequently Asked Questions

What turnover qualifies a business as a small manufacturer in the UK?

Most UK definitions set the ceiling at £10 million annual turnover, though some industry bodies use lower thresholds for specific sectors.

Can a small manufacturer qualify for Innovate UK grants?

Yes. Innovate UK offers several SME‑focused funding streams, especially for projects that involve new materials, digital manufacturing, or sustainability.

How many employees does a small manufacturer typically have?

Generally fewer than 50 staff, but many operate with just a handful of workers, especially in artisan‑focused niches.

What is the biggest advantage of staying small?

Flexibility. Small manufacturers can change designs, switch suppliers, or enter new markets much faster than larger firms bound by bureaucracy.

Do small manufacturers need to comply with EU/UK CE marking?

If the product falls under a regulated category-like electrical equipment or toys-then yes, CE marking (or the UKCA mark post‑Brexit) is mandatory regardless of company size.