What Is a Manufacturer? Definition, Examples, and Why It Matters in India

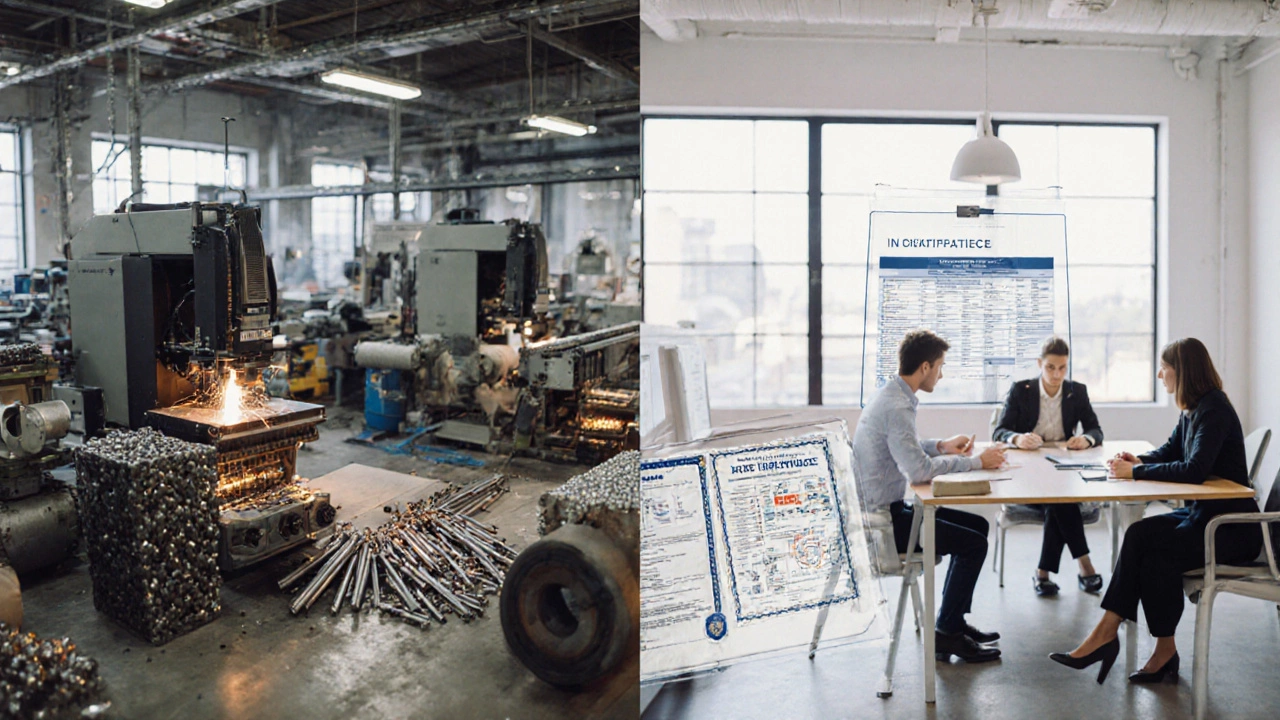

When you hear the word manufacturer, a business that turns raw materials or components into finished products for sale. Also known as a producer, it’s the hidden engine behind everything from your phone charger to the steel frame of a building. A manufacturer doesn’t just assemble parts—it solves problems. It takes scrap metal, plastic pellets, or cotton fibers and makes something useful, reliable, and often life-changing.

Not all manufacturers are big factories with smokestacks. In India, many of the most impactful manufacturers are small shops run by families or local entrepreneurs. They use simple machines, local labor, and smart design to make things like wooden furniture, metal brackets, or packaged snacks. These small manufacturers, businesses with fewer than 50 employees that produce goods locally. Also known as cottage industries, they’re the backbone of India’s rural and semi-urban economy. Think of a workshop in Gujarat making textile machinery parts, or a family in Tamil Nadu turning recycled plastic into garden chairs. These aren’t just businesses—they’re innovation labs with low overhead and high grit.

What sets a good manufacturer apart? It’s not just how much they produce—it’s how well they control quality, manage waste, and adapt to demand. The best ones don’t wait for orders—they spot needs before customers do. That’s why India’s rise in global exports isn’t just about cheap labor. It’s about manufacturers who learned to make precision parts for medical devices, durable packaging for food, or affordable electronics components that meet international standards.

Manufacturing in India is changing fast. New policies in states like Gujarat and Tamil Nadu give tax breaks and training to small producers. Factories that once made only for local markets now ship abroad. And the rise of scrap-to-product businesses—like turning old tires into flooring or plastic waste into bricks—shows that modern manufacturing isn’t just about scale. It’s about creativity, reuse, and smart resource use.

You’ll find stories here about who leads steel fabrication in the U.S., why India is becoming a top furniture exporter, and how chemical demand is shifting across states. You’ll see how food processing turns raw ingredients into shelf-stable goods, and how a single person with a machine and a plan can build a profitable business with almost no money. These aren’t just case studies—they’re blueprints for anyone who wants to make something real, sell it locally, and grow from there.

If you’ve ever wondered how your coffee mug got made, or why some products cost less in India than elsewhere, the answer starts with the manufacturer. This collection shows you how they work, where they thrive, and what it takes to join them.

What Qualifies as a Manufacturer? Clear Criteria and Real‑World Examples

Learn the exact legal criteria that define a manufacturer, from facility control to licensing, tax benefits, and real-world examples.

ManufacturingLatest Posts

Tags

- manufacturing

- small scale manufacturing

- plastic manufacturing

- India

- plastic pollution

- food processing

- textile industry

- government schemes

- electronics manufacturing

- small business

- steel manufacturing

- startup ideas

- production

- textile manufacturers India

- manufacturing business ideas

- business ideas

- chemical manufacturers India

- electronics manufacturing India

- steel manufacturing plants

- manufacturing business